Fast delivery Automatic China Carbon Steel Stainless Steel Pulse Arc MIG Welder DC Inverter portable Welding Machine

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Fast delivery Automatic China Carbon Steel Stainless Steel Pulse Arc MIG Welder DC Inverter portable Welding Machine, We usually concertrating on creating new creative solution to meet request from our clients everywhere in the earth. Be a part of us and let’s make driving safer and funnier alongside one another!

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for China Arc Welding Machine, Portable Mig Welding Machine, Our staffs are rich in experience and trained strictly, with specialist knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and specific service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we’ll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Function:

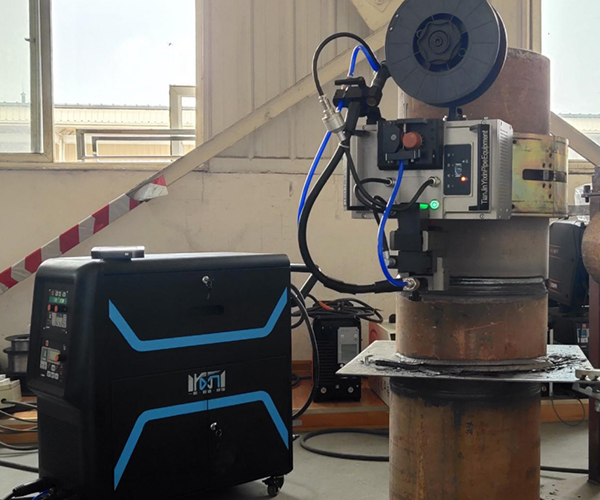

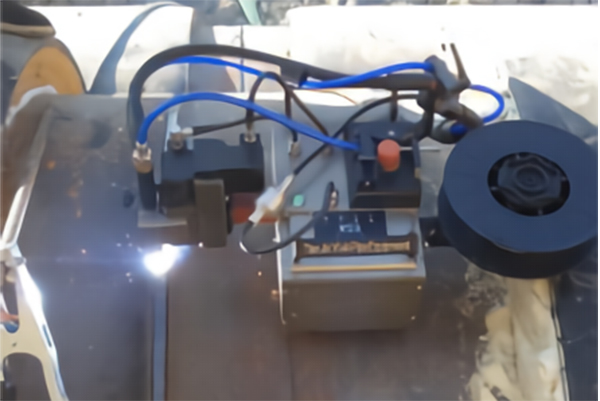

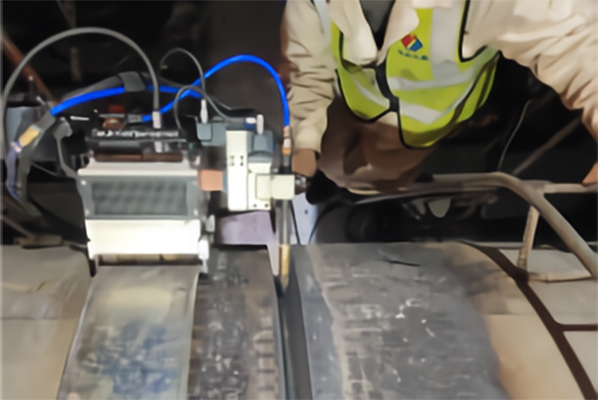

HW-ZD-200 series all position automatic pipeline welding machine is the latest masterpiece of the cooperation between Tianjin Yixin Pipe Equipment Co., Ltd. and Tsinghua University. It integrates more than ten patented technologies such as head automatic walking, electronic control system, and fault detection system. It can realize precise control of posture and time, intelligent gun swing function, even the ultra thick pipes can be welded with excellent welding quality. The maximum welding thickness can reach 100mm. It is a hot sale all position automatic welding machine in home and abroad,widely used in gas and natural oil pipe welding as first and great breakthrough. The whole system realizes integration optimization, adopts high-quality alloy steel shell of impact-resistant engineering, exclusive patented appearance design, exquisite and generous, compact and portable, and has a high degree of integration. All components can be integrated and stored in the outer box, which is convenient for on-site management and inter-project transportation; The base of the box is equipped with universal wheels, which is convenient for on-site movement and is suitable for various harsh welding environments.

Features:

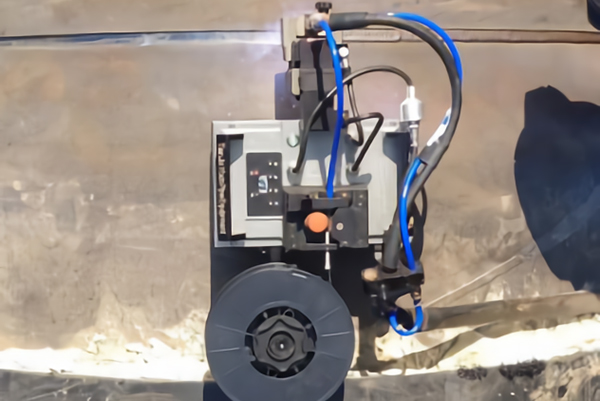

◆Integrated welding head with wire feeder: compact structure, stable wire feeding, strong arc stability, light overall weight

◆Data record: Realize 360°24 welding zone parameter presets, automatic reuse, to meet the GMAW/FCAW-GS welding process of various working conditions.

◆Applicable: 5-100mm thickness pipelines. OD: above 125mm (for fitting and cap)

◆Welding material: Carbon steel, stainless steel, alloy steel, low temperature steel.

◆Portable use: Small size and light weight. The portable design is suitable for field construction operation requirements.

◆On site work: The pipe is fixed and the magnetic head is crawling on the pipe, which realizes the automatic welding of the pipeline in all positions

◆High quality: The weld seam is beautifully formed, and the weld seam quality can meet the flaw detection requirements.

◆High efficiency: Welding efficiency increased by 400% (compared to traditional manual welding)

◆Wireless control: Using a high-definition 5-inch color touch screen interface, which can realize real-time editing, input, storage and recall of welding parameters

◆Easy operation:Easy training, quick start, reducing dependence on scarce and highly skilled welders

◆Detection test: The weld quality meets UT/RT and other flaw detection tests.

Technical Parameters:

Welding head

| Type | HW-ZD-200 |

| Operating voltage | Rated voltage DC12-35V Typical DC24rated power:<100W |

| Current control range | Equal or Higher than 80A lower than 500A |

| Voltage control range | 16V-35V |

| Swing speed | 0-50 Continuously adjustable |

| Swing width | 2mm-30mm Continuously adjustable |

| Left timing | 0-2s Continuously adjustable |

| Right timing | 0-2s Continuously adjustable |

| Gun swing speed | 0-50 Continuously adjustable |

| Arm shifting wide | 2mm-15mm Continuously adjustable |

| Welding speed | 50-900mm/min, Unlimited adjustable |

| Applicable pipe diameter | DN114mm above |

| Applicable wall thickness | 5-100mm |

| Applicable material | Carbon steel, stainless steel, alloy steel, low temperature steel, etc. (Stainless steel customized track) |

| Application | Various pipe section welds, such as pipe-to-pipe welds, pipe-to-elbow welds, pipe-to-flange welds (if necessary, transitional joints with fake pipes) |

| Welding wire(φmm) | 1.0-1.2mm |

| Operating temperature | -20℃…+60℃ |

| storage temperature | -20℃…+60℃ |

| Dimensions(L*W*H) | Welding head 350mm*260mm*300mm (with wire feeder) |

| Weight | Welding head 15Kg |

Power Supply

|

Type |

Power Control System |

|

| Power voltage | 3~50/60Hz | 400V-15%…+20% |

| Rated power | 60%ED100%ED 16KVA | 22.1KVA16.0KVA |

| Fuse (delayed) | 35A | |

| Output 60% temporary load rate | 60%ED100%ED | 500A390A |

| Welding current and voltage range | MIG | 10V-50V10A-500A |

| No-load voltage | MIG/MAG/Pulse | 80V |

| No-load power | 100W | |

| Power factor (maximum current) | 0.9 | |

| Efficiency (maximum current) | - | 88% |

| Storage temperature range | -40℃~+60℃ | |

| EMC level | A | |

| Total current minimum short-circuit capacity Ssc* | 5.5MVA | |

| Protection Grade | IP23S | |

| Dimensions | L*W*H | 830mm*400mm*370mm |

| Voltage supply for auxiliary devices | 50VDC/100W | |

| Voltage supply for cooling device | 24DC/50VA | |

Comparison

|

Manual welding |

Automatic Welding |

||

| Advantage | Disadvantage | Advantage | Disadvantage |

| Simple equipment, simple to set up | High skill required | Magnetic automatic technology, simple and portable use, without track | Wind protection needed |

| Portable/east to move | Long training cycle | Higher efficiency: 3-4 times faster than manual welding | Higher cost in one time (but reduce the cost of welders and materials) |

| versatile | Higher cost of labor | Save welding material: wire, gas, and so on. | |

| Excellent outdoor | Poor welding quality | Reduce welding labor force and labor cost, continuous welding saves time | |

| Excellent mechanical properties | Bad welding appearance | Raise productivity and reduce welding cost, reliable quality and good shape forms | |

| Excellent puddle control in all positions | High time costs and harder work | Low skill required and one button start | |

| Wide range of material | Less parts, easy to move | ||

On Site Work

Training for better results

We can train your operator to handle the welding machine( operators with basic welding experience are available). Once everything is well done, you are ready for start your welding.

Maintenance

We take the continuity of your company seriously. Therefore we offer several maintenance solutions. First of all, your employees are trained to do the regular maintenance themselves. If there are any problems, we can offer the next options.

1. Thanks to the online environment, we can give solutions online to solve problems from a distance. We can offer telephonic support to assist your operators.

2. If there are any troubles, we can handle asap. If there are something that we cannot handle online, we can also offer on site training.With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Fast delivery Automatic China Carbon Steel Stainless Steel Pulse Arc MIG Welder DC Inverter portable Welding Machine, We usually concertrating on creating new creative solution to meet request from our clients everywhere in the earth. Be a part of us and let’s make driving safer and funnier alongside one another!

Fast delivery China Arc Welding Machine, portable mig Welding Machine, Our staffs are rich in experience and trained strictly, with specialist knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and specific service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we’ll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.