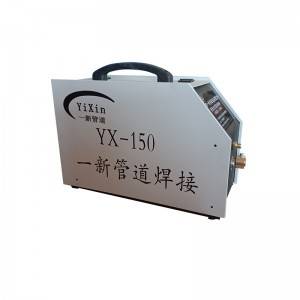

Low Cost China All Position Automatic Pipeline Welding Head Welding Machine Magnetic Absorbed in Stock

We try for excellence, services the customers", hopes to become the ideal cooperation team and dominator company for staff, suppliers and buyers, realizes value share and continuous marketing for Low Cost China All Position Automatic Pipeline Welding Head Welding Machine Magnetic Absorbed in Stock, We sincerely welcome all guests to setup business enterprise interactions with us around the basis of mutual positive aspects. Remember to speak to us now. You'll get our qualified reply within just 8 several hours.

We try for excellence, services the customers", hopes to become the ideal cooperation team and dominator company for staff, suppliers and buyers, realizes value share and continuous marketing for China automatic Welding Head, Welding Machine, Today, We have been with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Function:

The YX-150 series all position automatic pipeline welding machine is suitable for pipelines above DN114mm and wall thickness greater than 5mm. The pipeline is fixed and the welding head crawls autonomously to realize automatic all-position welding (5G welding)

Features:

◆ Applicable pipelines: Various kinds of long transportation pipeline, heat distribution pipeline, underground pipeline, process pipeline and so on, suitable for welding on site.

◆ Welding material: Carbon steel, stainless steel, alloy steel, low temperature steel.

◆ Applicable weld: Pipe diameter over 150mm, wall thickness over 8mm, Thick wall pipes can be welded in fitting and caps.

◆ Welding head: Easy to carry and transport, permanent magnet absorption and applicable for automatically welding on site.

◆ Remote-controlled: Set and control welding parameters on remote, easy to learn and operate with low labor intensity.

◆ High efficiency: Efficient welding and lower time 3-4 times than manual arc welding.

◆ High quality: The weld has great appearance, no porosity, slag inclusion, lack of fusion and other phenomena. The welding quality is good, and the qualified rate of ultrasonic flaw detection is over 97%. Meet the requirements of pressure test or impact, tensile, bending and other mechanical properties inspection.

Technical Parameters:

| Model | YX-150 |

| Working Voltage | Rated Voltage DC12-35V Normal: DC24 Rated Power:<100W |

| Current Range | 80A-500A |

| Voltage Range | 16V-35V |

| Welding gun Swing Speed | 0-100 Continuing Adjust |

| Welding gun Swing Width | 2mm-30mmContinuing Adjust |

| Left Timing | 0-2sContinuing Adjust |

| Right Timing | 0-2sContinuing Adjust |

| Welding Speed | 0-99(0-750)mm/min |

| Applicable Pipe Diameter | More than DN150mm |

| Applicable Wall Thickness | 8mm-50mm |

| Applicable Material | Carbon steel, stainless steel, alloy steel, low temperature steel, etc.(stainless steel customizable track) |

| Applicable welding line | All kinds of pipe segment welds, such as pipe-pipe welds, pipe-elbow welds, pipe-flange welds, (if necessary, adopt dummy pipe transition connection) |

| welding wire(φmm) | 1.0-1.2mm |

| Size(L*W*H) | Welding head230x140x120mm |

| Weight(KG) | Welding head 11kg |

Comparison:

| Manual welding | Automatic Welding | ||

| Advantage | Disadvantage | Advantage | Disadvantage |

| Simple equipment, simple to set up | High skill required | Magnetic automatic technology, simple and portable use, without track | Wind protection needed |

| Portable/east to move | Long training cycle | Higher efficiency: 3-4 times faster than manual welding | Higher cost in one time (but reduce the cost of welders and materials) |

| versatile | Higher cost of labor | Save welding material: wire, gas, and so on. | |

| Excellent outdoor | Poor welding quality | Reduce welding labor force and labor cost, continuous welding saves time | |

| Excellent mechanical properties | Bad welding appearance | Raise productivity and reduce welding cost, reliable quality and good shape forms | |

| Excellent puddle control in all positions | High time costs and harder work | Low skill required and one button start | |

| Wide range of material | Less parts, easy to move | ||

On Site Work