Tube To Tube Sheet Automatic Argon Arc Welding Machine

YXWZM1-400C type tube to tube sheet all-position automatic pulse tungsten argon arc welding machine is a special equipment developed for the production of heat exchangers in petroleum, chemical, power station, boiler, refrigeration, atomic energy and light industrial machinery industries.

This type of tube to tube sheet automatic welding machine is mainly used for the welding of tube and tube sheet. The whole welding process is automatically carried out according to the preset procedures and process specifications, and the welding process is directly displayed by the seven-inch color LCD touch screen, with a high degree of automation.

Equipment Composition:

The complete set of equipment consists of power supply numerical control cabinet, welding head, gantry operation frame, remote control button box, circulating water cooling device and water and air pipe accessories.

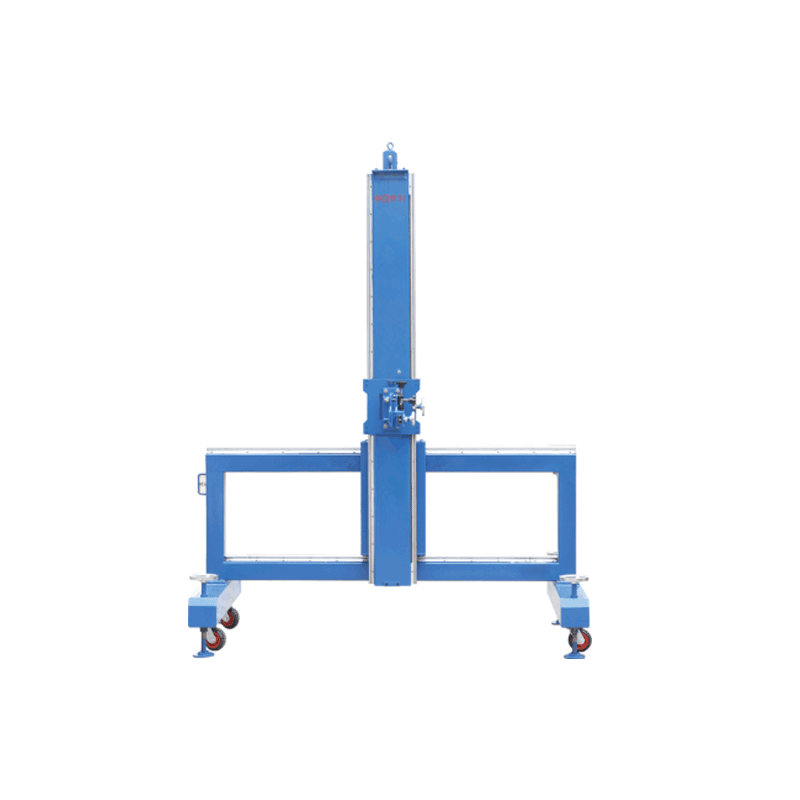

Gantry Operation Rack

Power Source

Remote Control Box

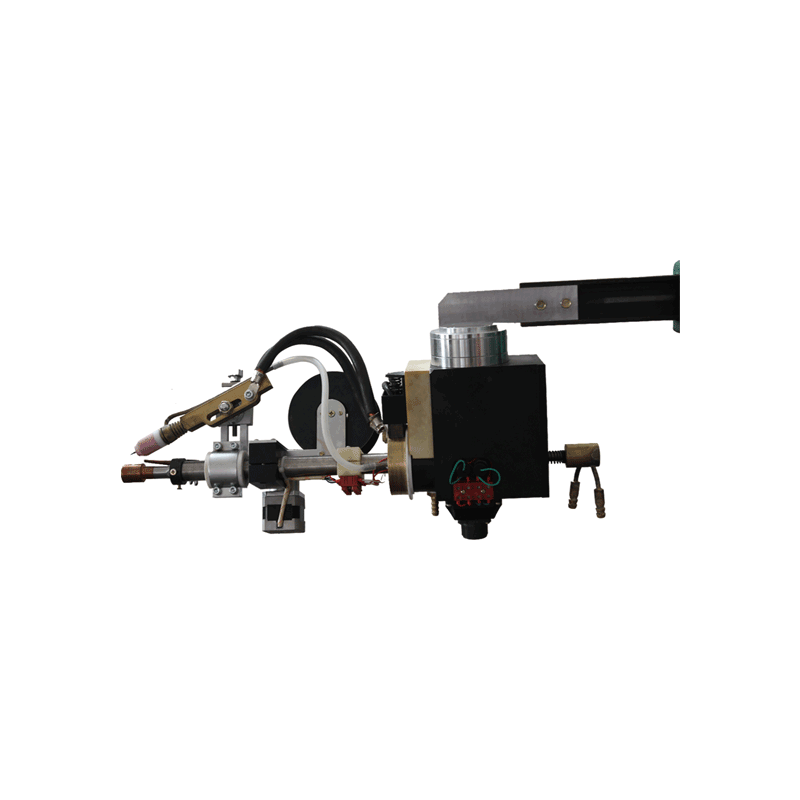

Welding Head

Circulating water cooling device

The input of welding process parameters and the display of welding process adopts touch screen technology.

The machine head (welding head) adopts circulating water to cool the mandrel, which can not only meet the fillet welding of thin-walled tubes but also take away the heat of the machine head, so the machine can work for a long time without interruption

It has the function of welding starting point memory. After the welding of one nozzle is completed, the machine head will automatically rotate, and the current will attenuate the angle turned by the machine head and the overlap angle of the welding seam, and return to the starting position of welding, which is convenient for the next opening. welding

The process of each welding cycle of the welding machine can be divided into eight sections, and the pulse base and peak current can be set in sections.

The equipment can weld three types of welding including flat welding, fillet welding and hidden welding.

This machine is controlled by Siemens PLC (Programmable Logic Controller), which can store 99 kinds of process parameters, which is convenient to search and call. Each parameter can be used after modification or stored after modification.