News

-

The Advantages Of Automatic Welding

Automatic pipeline welding machines have revolutionized the welding industry, and their use has become increasingly popular in recent years. Welding is a crucial process in the construction, repair, and maintenance of pipelines, and the use of automatic welding machines ...Read more -

Welding Advantages Of Automatic Pipeline Welding Machine

What are the advantages of an automatic pipeline welding machine? Automatic pipeline welding machine, also known as automatic pipe welding machine, pipe welding machine automatic, automated pipe welding, automatic pipeline welding, auto pipe welding machine, pipe welder ...Read more -

The Advantages Of Fully Automatic Pipeline Welding Machine

What is a fully automatic pipeline welding machine? Fully automatic pipeline welding machine, also known as automatic pipeline welding machine, orbital automatic welding machine, pipeline welding machine, pipeline automatic welding equipment, automatic welding head, automatic welding robot, autom...Read more -

How Powerful is Tianjin Yixin Closed Type Tube to Tube Automatic Welding Equipment?

You must have heard of the term welding. Are sparks flying and smoke billowing your inherent impression of welding? Welding equipment is also known as "industrial sewing machines" and has a very high status in the industry. Through automation technology, welding becomes ...Read more -

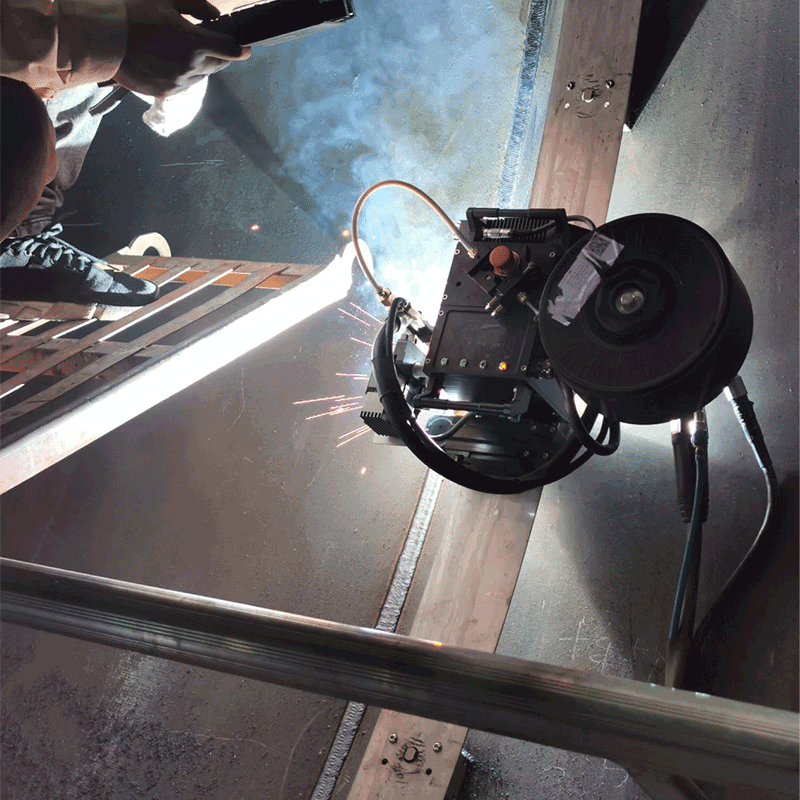

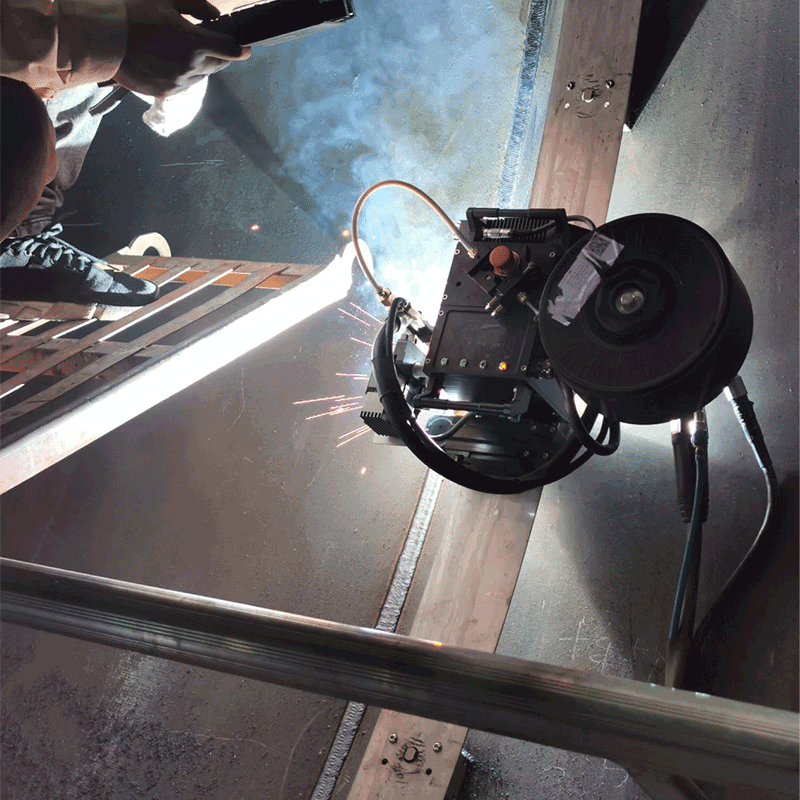

Application of Tianjin Yixin All-position Automatic Pipeline Welding System in Large Water Resources Allocation Project Site

With the construction, renewal, and transformation of urban municipal pipe networks, the amount of groundwater allocation projects has increased dramatically, ushering in a period of large-scale ...Read more -

Advantages 0f Automatic Welding Technology With the continuous advancement of modern science a

With the continuous advancement of modern science and technology, the application of automation technology in people's lives is becoming more and more extensive, and the application range in the welding industry is also expanding. ...Read more -

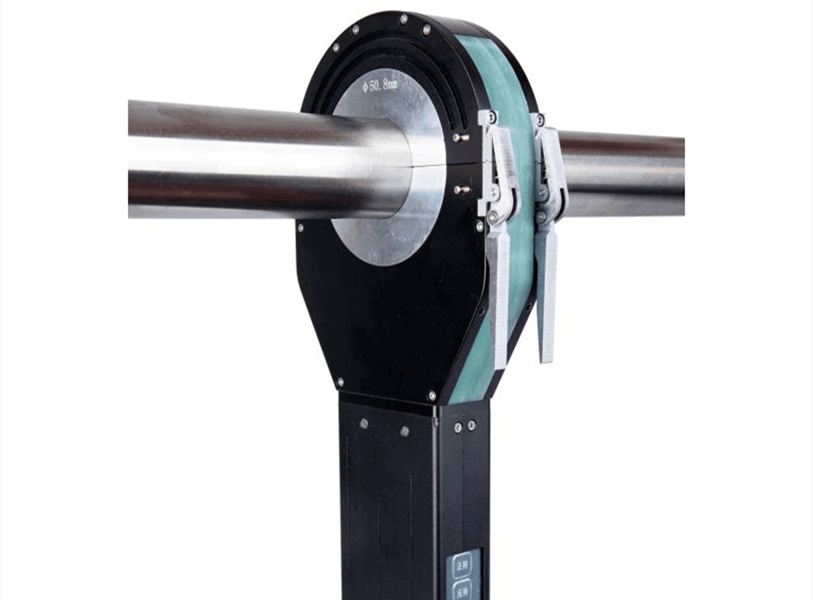

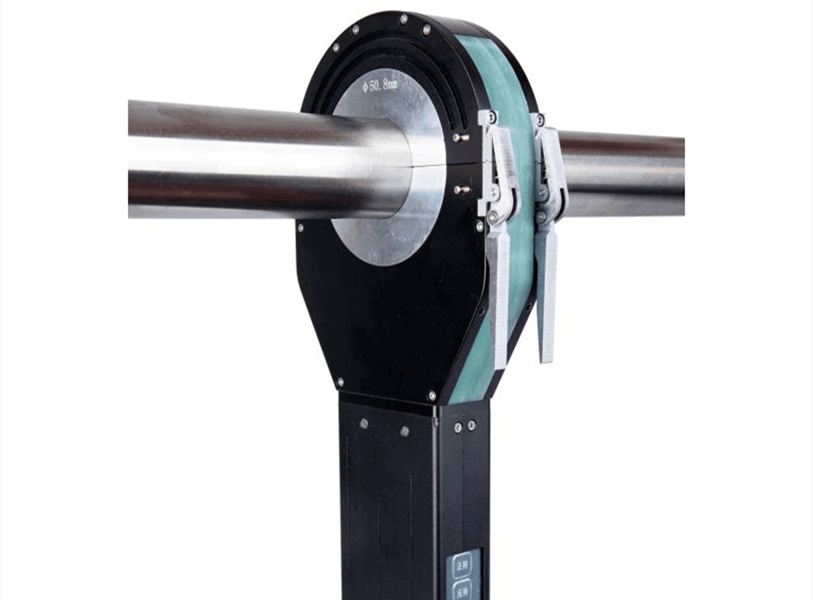

What Is A Closed Type Automatic Pipe Welding Machine

Tianjin Yixin closed type automatic pipe welding machine (also known as closed type orbital welding machine, orbital welding machine, automatic tube welding machine, stainless steel tube welding, tube to tube orbital welding head, closed type orbital welding head, closed...Read more -

Brief Introduction of Tianjin Yixin Closed Pipe and Pipe Automatic Welding Machine

With the increasing demand for welding, people have higher and higher requirements for the degree of intelligence and stability of the welding machine. Tianjin Yixin Closed type pipe and pipe automatic welding machine is a special developed by Tianjin Yixin for automatic...Read more -

The Principle And Advantages Of Closed Type Orbital Pipe Welding Machine

Tianjin Yixin Pipe Equipment Co., Ltd. specializes in the production of various types of closed type orbital welding machine, automatic pipe welding equipment, automatic pipe and pipe welding machines, all-position automatic welding machines, all-position pipe and pipe w...Read more -

Advantages Of Closed Type Orbital Welding Machine

With the continuous improvement of people’s living standards, automation has gradually penetrated all aspects of our lives. As an indispensable link in the pipeline installation process, pipeline welding is gradually becoming automated. What are the advantages of automatic welding equipment...Read more -

Closed Type Automatic Pipe Welding Machine

Tianjin YIXIN closed type small pipe automatic welding machine (self-fluxing argon arc welding machine) ,can be used for all-position automatic welding of pipes of various materials such as carbon steel, stainless steel and so on. The welding process is simple and fast, and high quality can be c...Read more -

Development Trend of Automatic Pipe Welding Equipment

With the improvement of people's living standards, people's demand for oil and natural gas is also increasing, and the pipeline installation tasks of long-distance pipelines such as petrochemical natural gas are becoming more and more important. In addition, oil and gas ...Read more